More efficiency, less criticity and more competitiveness

Quality and performance are the key factors making more competitive each production dimension.

The aims of our MES modules are: following the production flows to guide operations and reduce errors due to inefficient management.

These modules allow to monitor the whole life cycle of the product: its creation and identification, assembly and testing operations, routing towards the bays of end of line and production declaration.

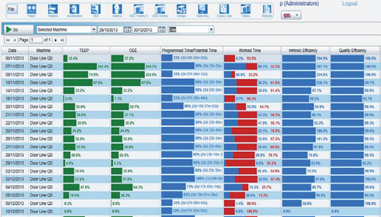

Each phase is kept under control thanks to OEE indicators able to measure and monitor the efficiency of production processes and compare results.

Websolute

Websolute